Calibrated Underpacking Papers

Calibrated Underpacking Sheets

marks-3zet Calibrated Underpacking Sheets The original Of The Inventor

Huaguang Flexographic Printing Plates are high-quality plates manufactured by Lucky Huaguang Graphics Co., Ltd., a leading Chinese company specializing in printing technologies. These plates are designed for various flexographic printing applications, including packaging, labels, and commercial printing.

-

For an optimum printing result in the offset printing process, among others, the absolutely even pressure of the printing cylinders against the entire area is the decisive factor. Irregularities lead to stripes or cloudy spot, to thrusting and folding, to fluctuating dot gain etc. Underpacking sheets having different thicknesses ensure the proper pressure. The accurate and uniform property of the papers as far as possible with regard to density, surface and thickness is important.

Technology of the offset printing

-

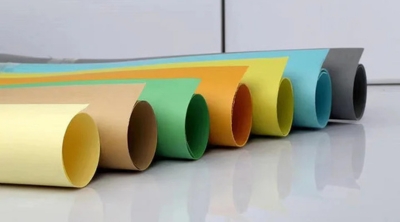

No willingness to compromise in the precision: marks-3zet underpacking sheets are manufactured in accordance with ISO Standards for calibrated materials. In this process irregularities are eliminated and the paper is compressed to a minimum of its volume. The required tolerances of ± 0,01 mm/m² are not only achieved, but clearly fall below. Only the original provides optimal results: For a smooth printing process underpacking sheets in different thicknesses are required. The thicknesses vary in the hundredth millimeter range and lie between 0.075 and 0.5mm. marks-3zet’s color scheme with 10 different underpacking sheets has two advantages: It enables to work completely without measuring tools and facilitates to find the correct underpacking sheet to prevent production faults.

Precision and quality

-

In addition to the precision and function the underpacking sheets of marks-3zet meet additional necessary requirements for an optimal product: They are safe, reliable, faultfree and unique as a whole. Safe because „Anti-slip“ reduces slip – reliable because the special impregnation any possible bunching up of the underpacking sheets – problems through thrusting and twisting are prevented through the compressive strength of the paper. Unique because marks-3zet with its experience from more than sixty years and many patented methods has developed a top-class product.

Perfection of the inventor

light blue 0,075mm

grain-coloured 0,10mm

light brown 0,125mm

brown 0,15mm

rose-coloured 0,175mm

Precise!

- Special method (Calibration) eliminates irregularities

- All papers are absolutely uniform in hardness and thickness

- Filled ISO standards for calibrated materials

- Falls below the required tolerances of ± 0.01mm/m²

Functional!

- Patented color scheme by the Inventor

- 10 different thicknesses (0.075mm – 0.5mm) for optimal pressure

- Color scheme facilitates the printing machine setting

- Color scheme prevents production faults

Safe!

- Anti-slip coating for optimal result

- Prevents slipping of the underpacking sheets

- No thrust in the machine

- No twisting in the machine

Reliable!

- Through and through impregnation

- Prevents moisture penetration

- Prevents undesired tendency to bunching up

Unique!

- More than 60 years experience

- Patented manufacturing methods

- Original quality from the Inventor

- Worldwide Number One

Faultless!

- High paper hardness through calibrated method

- Compressive strength 60t/cm²

- Prevents thrusting

- Prevents twisting

- Prevents high dot gains

light blue 0,075mm

grain-coloured 0,10mm

light brown 0,125mm

brown 0,15mm

rose-coloured 0,175mm